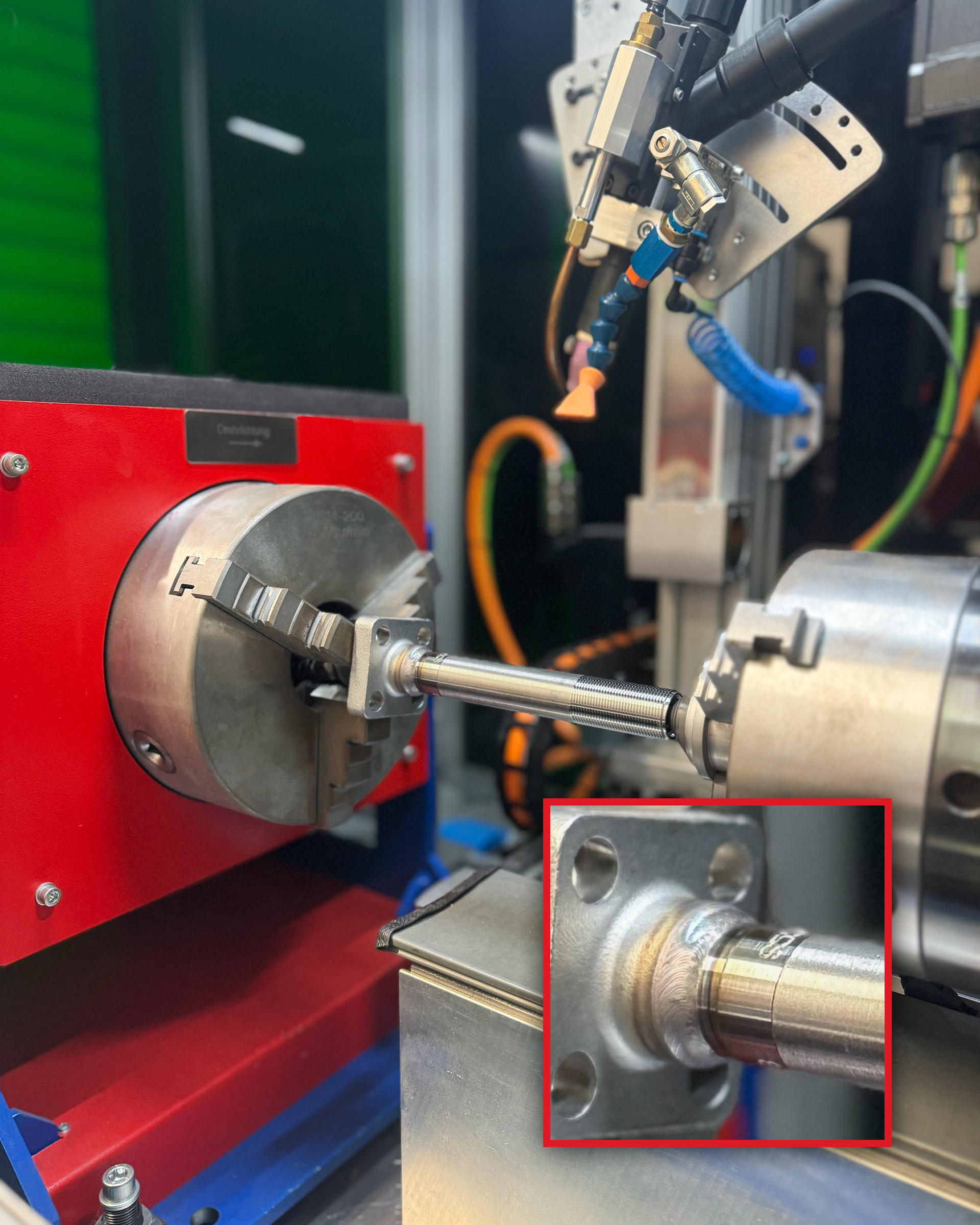

Technical News 01/08/2024Welding at GOETZE - precision that convinces!

Get a deeper insight into welding at GOETZE.

Good to know! - Precision and innovation in welding

Our in-house welding shop at GOETZE is a central component of our production processes. It enables us to react flexibly and efficiently to errors and adjustments, resulting in significant time and cost savings for our customers.

Why do we have an in-house welding shop and why is it so important?

- Flexibility: Fast response times for troubleshooting and customisation.

- Quality: Certified welding technology for pressurised parts.

- Efficiency: Time and cost savings for our customers.

Our welding work is mainly focussed on stainless steel, the primary material for our customer products. For maintenance work, we can also process aluminium and normal steel.

The main series for our welding work include the 4000 and 400 series as well as the 2140 shut-off valves. Occasionally we also weld components from other series to fulfil special customer requirements or maintenance and development projects.

We rely on the highest quality and innovative welding processes to ensure that our products meet the highest standards..

We then ensure maximum cleaning and corrosion resistance by passivating the weld seams.