FAQ

Sealing Materials

Here you will find answers to questions about sealing materials that we are asked particularly frequently.

In case you have a special questions please contact us. We will be pleased to help you and give you our advice.

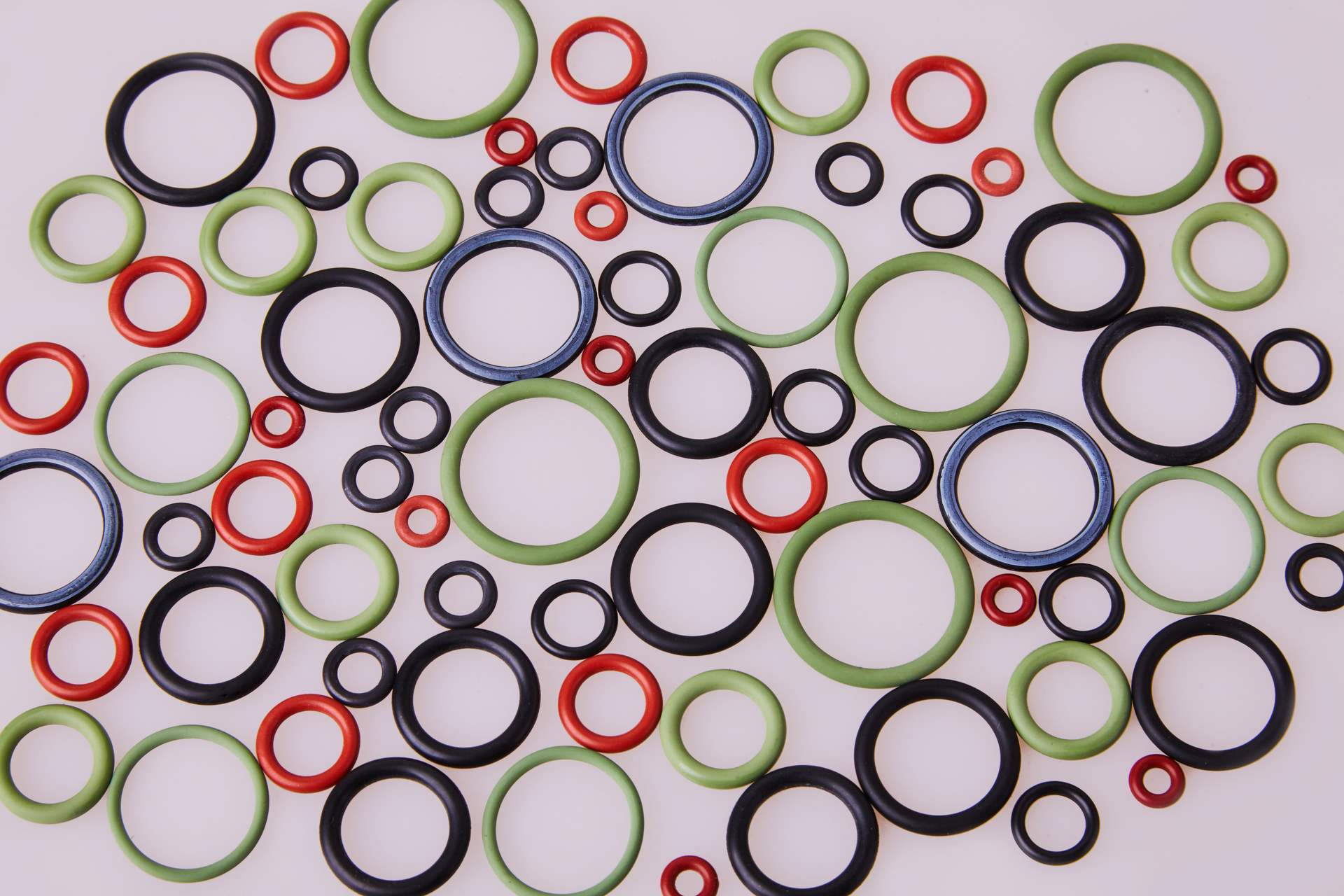

SEALINGS

Seals are there to ensure the tightness of components. But why are there so many of them?

The answer is quite simple: The suitable sealing material depends on the medium, the temperature and/or the pressure under which the valve has to operate and guarantee safety.

Some of the sealing materials are barely resistant against chemical products, while others prove the opposite and can also withstand extreme temperatures and high pressures:

NBR | Nitrile Butadiene Rubber

NBR has good resistance to media like hydraulic oils, mineral oils, mineral oil products, oil in water emulsions, water glycols, animal as well as vegetable oils and petrol. NBR has good mechanical properties making it a versatile sealant. Depending on the type of use the temperature range is 30 °C to +130 °C.

FPM | Fluorcarbon-polymere

FPM has excellent resistance to high temperatures, oxygen, mineral oils, synthetic hydraulic fluids, fuels, aromatics, many organic solvents and chemicals. Although for water and steam the temperature limit is approx. +60 °C. Additionally, the low permeability to gas allows the use in high-vacuum applications. FPM is often a substitute material for NBR. Depending on the type of use the temperature range is -20 °C to +200 °C. Certain mixtures achieve values between -40 °C to +230 °C. For the use with oxygen, BAM tested materials are in use (BAM= “Bundesanstalt für Materialprüfung”, German institute for material testing).

EPDM | Ethylene-Propylene-Diene-Monomere Rubber

EPDM has good resistance to oxygen, diluted acids and many chemicals; however it is not applicable with mineral oils. With hot water and steam in closed circuits, temperatures up to 180 °C are possible. EPDM is often used in connection with foodstuffs (Manufacturer authorization according to FDA and elastomer guideline). Depending on the type of use the temperature range is -40 °C to +170 °C. For the use with oxygen, BAM tested materials are in use (BAM= “Bundesanstalt für Materialprüfung”, German institute for material testing).

FFKM | Perfluorelastomer

FFKM is a high performance elastomer with a similar high chemical resistance as PTFE. In addition, it has elastic properties. It is used mainly in applications for O-ring seals in the chemical industry, as well as the food industry with FDA approval. In addition, FFKM is resistant against steam. Depending on the type of use the temperature range is -10 °C to +260 °C.

PTFE | Polytetrafluorethylene

Generally, PTFE has an excellent chemical resistance. For the use with oxygen, BAM tested materials are in use. (BAM= “Bundesanstalt für Materialprüfung”, German institute for material testing). As sealing material it is only used in modified versions. Special advantages are the reduction of permeation and cold flow. Depending on the type of use the temperature range is -200 °C to +225 °C.

PTFE carbon | Polytetrafluorethylen Compound with carbon

By admixing carbon, significantly higher tensile strength values are achieved. In comparison to modified PTFE, this material is particularly more suitable with higher pressure loads and has a similar chemical resistance. Depending on the type of use the temperature range is -200 °C to +225 °C.

MD | Metal-to-metal sealing

In the case of metal to metal sealing, various materials can be used depending on the application. Special advantages are high temperature ranges and the same chemical resistance as the material of the valve body. Depending on the type of use the temperature range is -270 °C to +400 °C.