FAQ Welding

Welding processes at GOETZE - precise and clean

Here you will find answers to the questions we are most frequently asked about welding.

If you have a specific question, please send us an e-mail and we will be happy to help.

Welding at GOETZE – Which materials and series do we weld?

At GOETZE, we rely on high-precision welding processes to ensure the quality of our products. Our welding work is mainly focused on stainless steel, the primary material for our customer products.

For maintenance work, we can also process aluminium and normal steel.

The main series for our welding work include the series 4000 and 400 as well as the shut-off valves 2140. Occasionally, we also weld components from other series to meet special customer requirements or to fulfil maintenance and development projects.

What are the advantages of in-house welding?

Our in-house welding shop offers significant advantages in terms of flexibility and time savings, which directly benefit our customers. We can respond quickly and precisely to errors, while always meeting high standards such as ASME approval. Each welded product is 100% tested to ensure the highest quality.

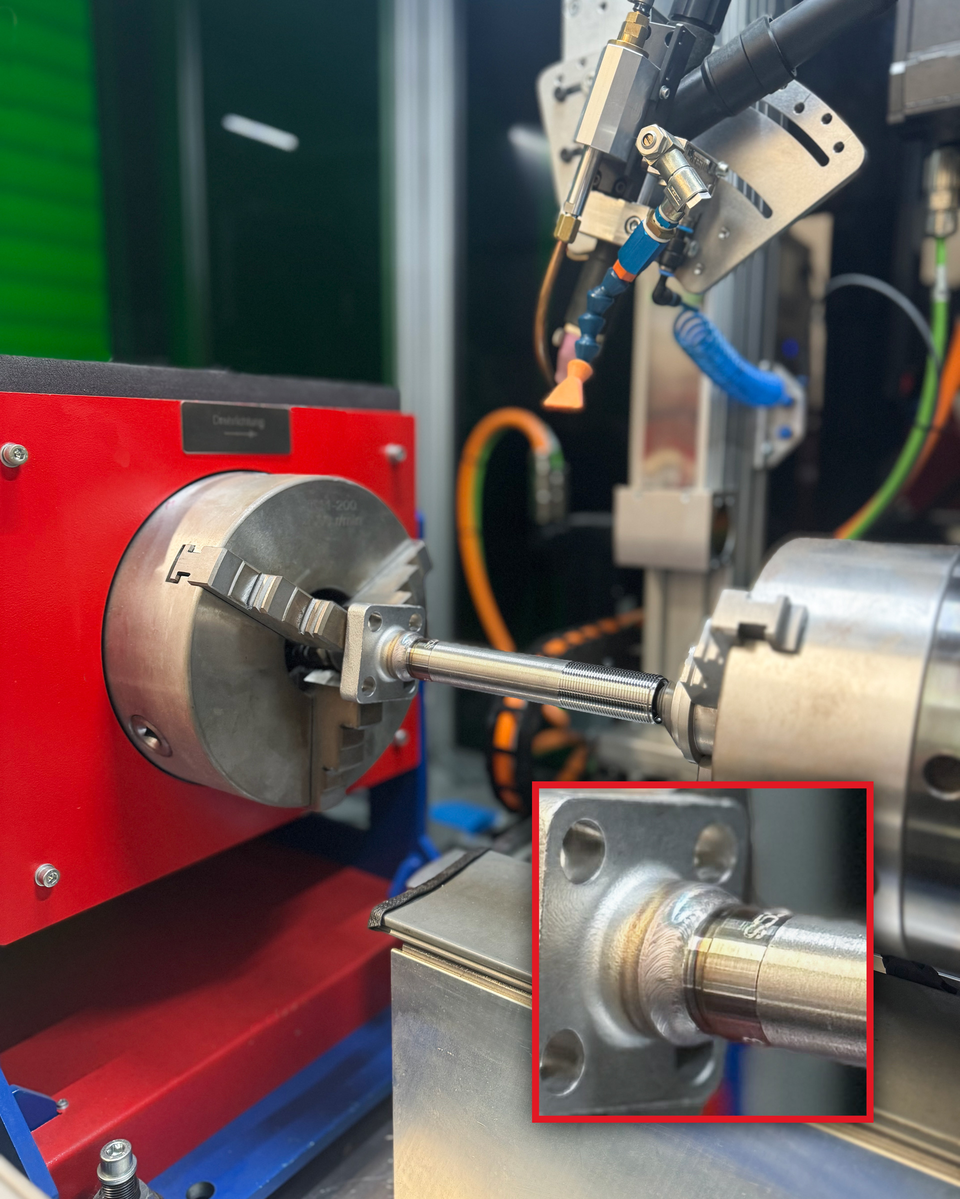

GOETZE is certified to weld pressure-bearing parts and has its welding technology inspected annually. In addition to manual welding processes, we also use orbital machines that enable uniform and precise weld seams. TIG welding also allows root welding, which is often not permitted with other processes.

HOW ARE THE VALVES CLEANED?Passivation after welding

At GOETZE, we place great emphasis on thoroughly cleaning and passivating the weld seams after the welding process. Our high-quality stainless steel valves undergo a careful treatment in an electrolytic solution that removes any residue and protects the surface of the welds. This passivation process forms a protective layer on the stainless steel that prevents corrosion and ensures the longevity of our products.

Through this meticulous post-treatment, we guarantee that our valves are spotlessly clean and meet the highest aseptic standards.