FAQ Leakage and leak testing

Leakage rates and helium leak test - you are safe with GOETZE

Here you will find answers to questions that we are frequently asked about leaks and leak tests.

If you have a specific question, please send us an E-Mail and we will be happy to help you.

What is a leak? - Definition according to DIN EN 1330-8

In non-destructive testing technology, a leak is a porous area, a hole, a gas-permeable area or another structure in the wall of a test object through which solids, liquids or gases can enter or escape undesirably due to a pressure difference or a concentration difference.

Leakage rate

The leakage rate, also referred to as leakage rate or leakage flow, indicates the amount of a certain medium (such as gas or liquid) that outlets through a leak in a closed system per unit of time.

The leakage rate is an important parameter in leak tests and plays a decisive role in assessing the integrity of closed systems.

Measuring units

for gases: Millibar litres per second (mbar∙L/s)

for liquids: Millilitres per second (ml/s)

Display mbar.l/s

Conversion: 1x10-4mbar.l/s = 0.0001mbar.l/s = 0.0000001bar.l/s

Leakage units

SI standard = mol/s (1 mol = 6.025.1023 particles)

Fluid technology = Nm/s, sccm, sccs

Vacuum technology = Pa m3/s, mbar l/s, Torr l/s, atm cc/s

Air conditioning = g/a, oz/y

Concentration = ppm (no leakage rate unit)

Possible causes of leaks

- Hole or open pores in the chamber wall

- Crack (material defect)

- Welding defect, soldering defect

- Incorrectly tightened or not tightened screw connections

- Damaged or dirty seals

- Assembly errors, e.g. forgotten seal

- Incorrect choice of material (gas permeable)

Visualisation mbar.l/s

Outflow time of a bicycle tyre filled with air at the following leakage rates:

Tyre volume: 2 L

Tyre pressure: 3 bar

Temperature: 20 °C constant

2x10-4 mbar.l/s = 1 year

1x10-4 mbar.l/s = 2 years

1x10-5 mbar.l/s = 20 years

1x10-6 mbar.l/s = 200 years

1x10-7 mbar.l/s = 2000 years

1x10-8 mbar.l/s = 20000 years

If the bicycle tyre has a hole, a certain amount of air flows out. The leakage rate is shown in mbar.l/s at the top left of the list. On the right-hand side, the corresponding time in years is given, which indicates the period of time after which there is no more air in the tyre.

This example clearly shows how important it is to precisely evaluate the requirements for tightness.

Method

Foam patterns

Bubble test (API) nozzles Ø 6.12mm

Bubble test nozzle Ø 2.5mm

Pressure drop test

Helium leak test

Nachweisgrenze

1x10-3 mbar.l/s

1x10-3 mbar.l/s (1 bubble/ min.)

1x10-4 mbar.l/s (1 bubble/ 1.3 min.)

1x10-4 mbar.l/s

1x10-9 mbar.l/s (under optimum conditions)

What is a helium leak test?

The helium leak test is a method of identifying leaks in a sealed system by using helium gas as a trace gas. This method is particularly effective as the very small helium atoms can easily escape through the smallest openings or cracks.

The setup or test method depends on the location on the test specimen that is to be measured and must be considered separately in each case.

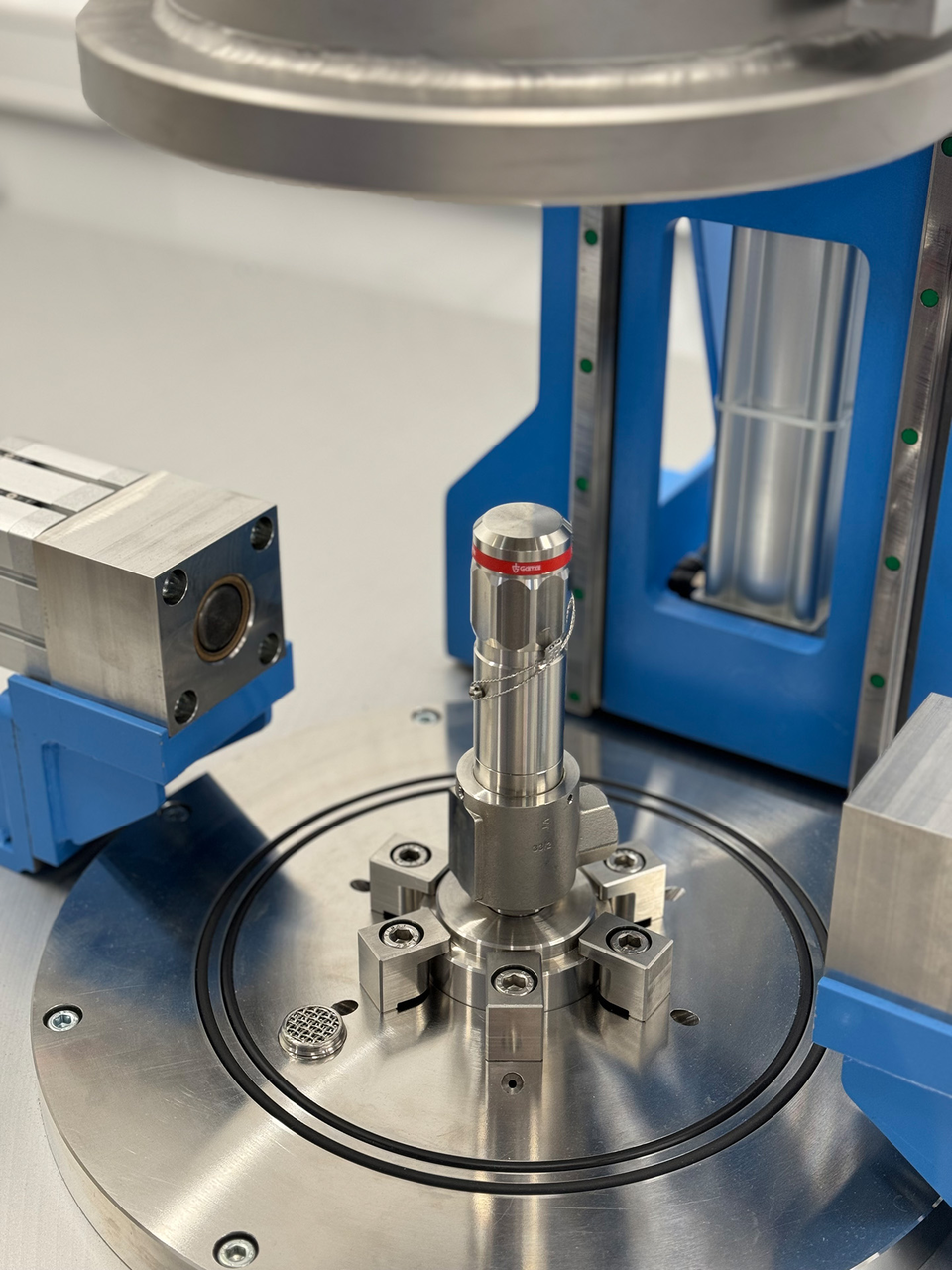

With our in-house helium test bench, we can detect the leakage rate of the seat seal of our safety valve 492 up to a leakage rate of 1×10-6 mbar.l/s at a test pressure of 50 to 1500 bar.