Precise 1:1 replacement of safety valves – retrofit solution with ASME approvalSafety valve replacement at tank farm in Thailand

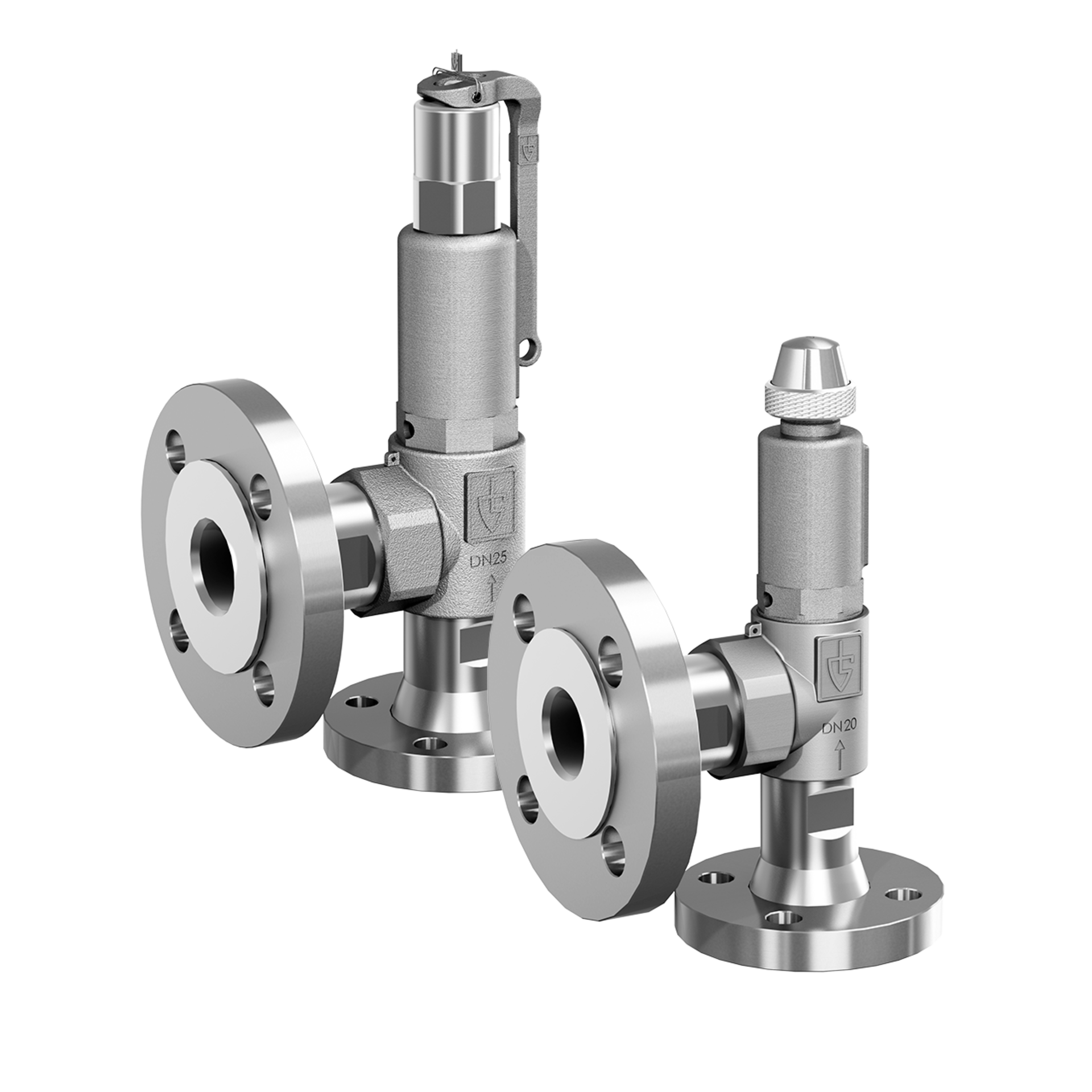

At a large tank farm in Thailand, 40 safety valves were replaced with Goetze series 451FL valves. Thanks to individually adapted flange dimensions, a precisely fitting 1:1 replacement was achieved – without any changes to the existing piping geometry. This project demonstrates how flexibly our valves can be adapted to different operating conditions and how easy it is to implement retrofit solutions with Goetze – quickly, reliably and ASME-certified.

The challenge: replacement without changing the system

Tank farms are hubs for energy supply. These facilities are subject to the most stringent pressure safety requirements: safety valves must work with absolute precision, fit seamlessly into the existing installation conditions and, at the same time, comply with international approvals such as ASME certification.

The challenge for this project was to find a solution that would replace the existing safety valves 1:1 without making any adjustments to the piping system.

The solution:Goetze Series 451FL

The Goetze 451FL safety valves with loose flanges were precisely adapted to the existing flange geometries. This meant that a retrofit replacement could be carried out with minimal effort.

You can find more technical details and information about the 451FL series on our product page.

Special features of implementation:

- Perfect 1:1 replacement thanks to special flange dimensions

- Sized for 30 psi for the specific pressure range

- ASME-certified safety for the international market

- Reliability in continuous operation with volatile media

- Design with loose flanges for maximum installation flexibility

If you are interested in using our valves with loose flanges, read more in our story:

Area of application Safety valves for hydrocarbons

The tank farm in Rayong stores hydrocarbons such as petrol, diesel and other fuels that are highly volatile. Here, safety valves must:

- respond precisely when excess pressure occurs

- operate reliably even under fluctuating temperatures and pressures

- be resistant to corrosive environments

The Goetze 451FL safety valve offers precisely these characteristics and is therefore used successfully not only in tank farms, but also in refineries, energy supply and industrial plants.

With the new valves, the tank farm is ensured for the long term and meets all international safety standards.

DO YOU HAVE ANY QUESTIONS? Looking forward to helping you!

Olaf Schulenberg

Business Development Manager

"I am responsible for the Industrial, Technical Gases and Cryogenic business units and support our customers with customised solutions and in the sizing of safety valves. I am also involved in standardisation committees and am responsible for the northern Germany and Netherlands sales region in the field service department."

Phone: +497141 48894670