Your processes are unique – so are our solutions.GOETZE diaphragm valves: Quality in detail

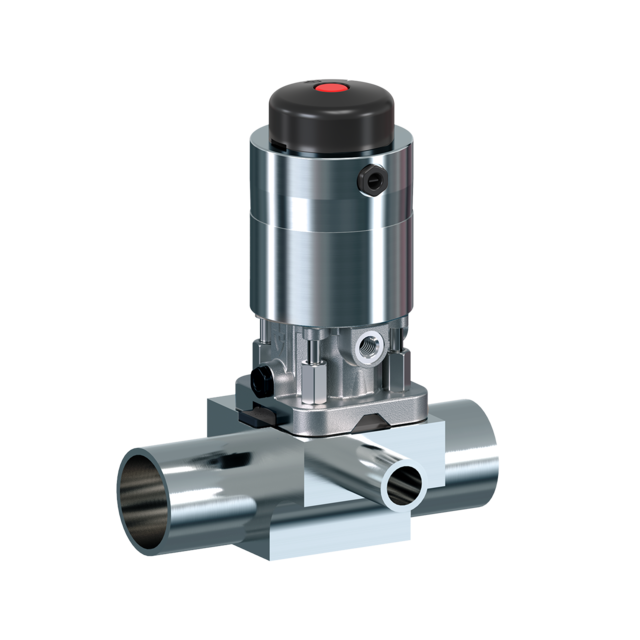

A new product group for the highest demandsPrecision and safety for aseptic processes.

In order to meet the complex requirements of hygiene-critical applications, we at Goetze have put together a specialized team of experts. This team combines expertise from the pharmaceutical, biotech, food & beverage, life science, and cosmetics industries. Our Diaphragm valves stand for technical precision, purity, and process safety. They are manufactured to the highest quality standards and are supported by our experts right from the planning phase – for maximum efficiency and safety.

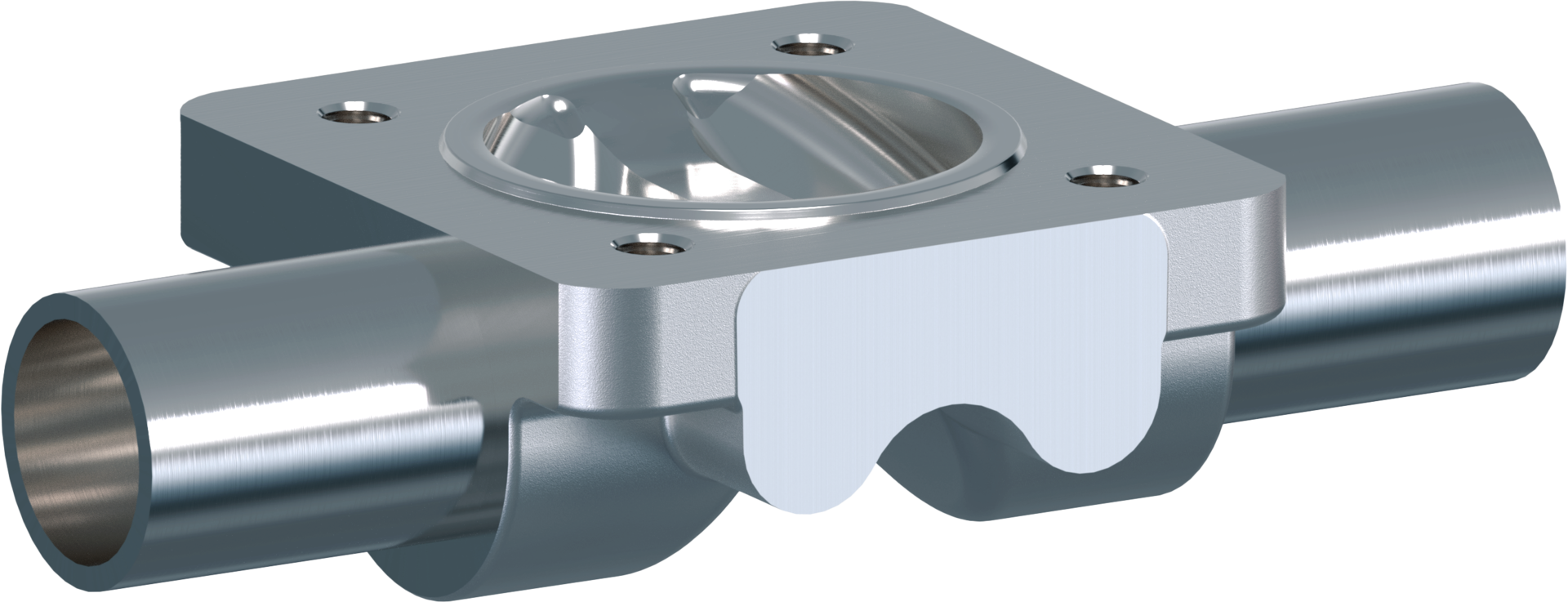

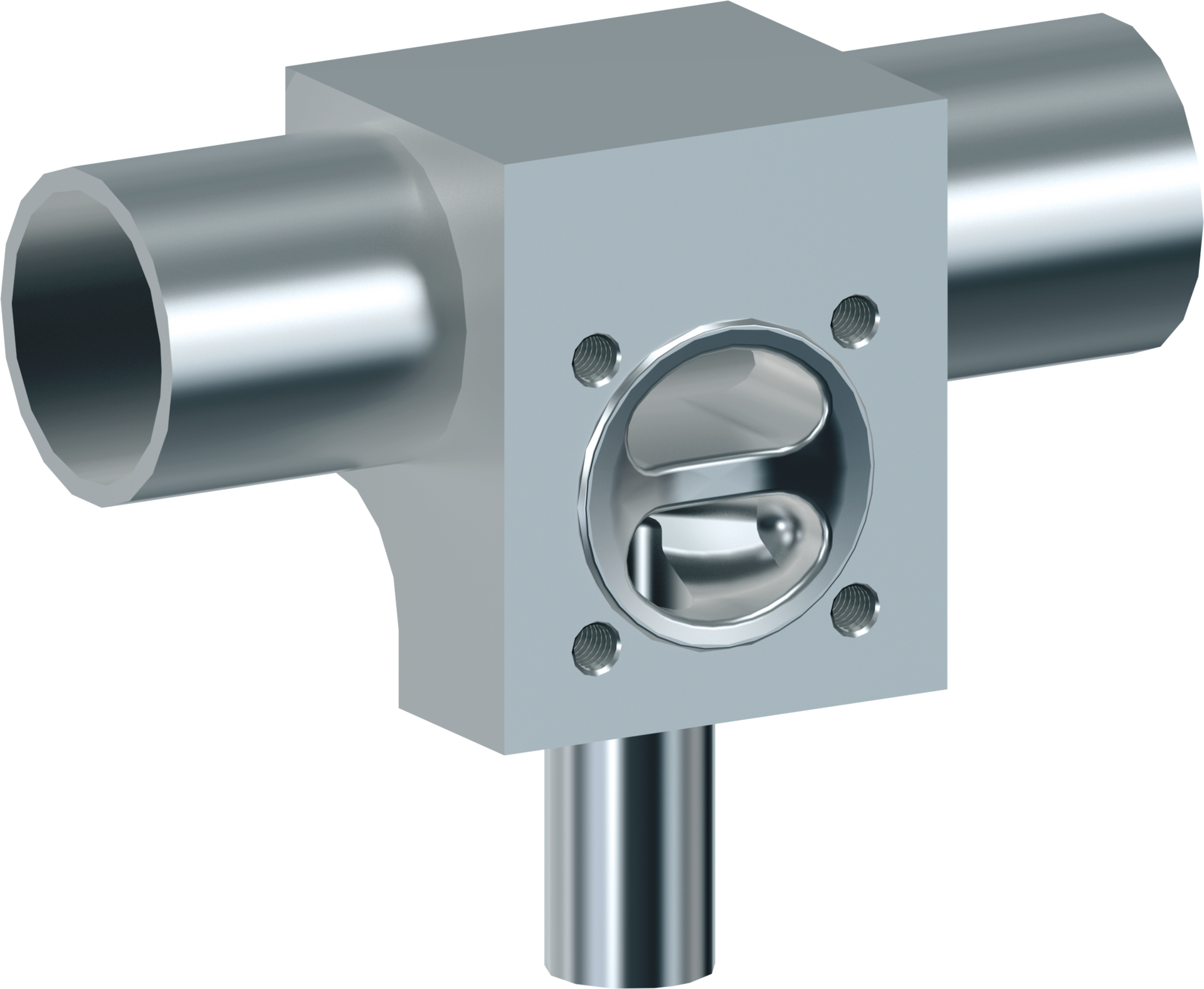

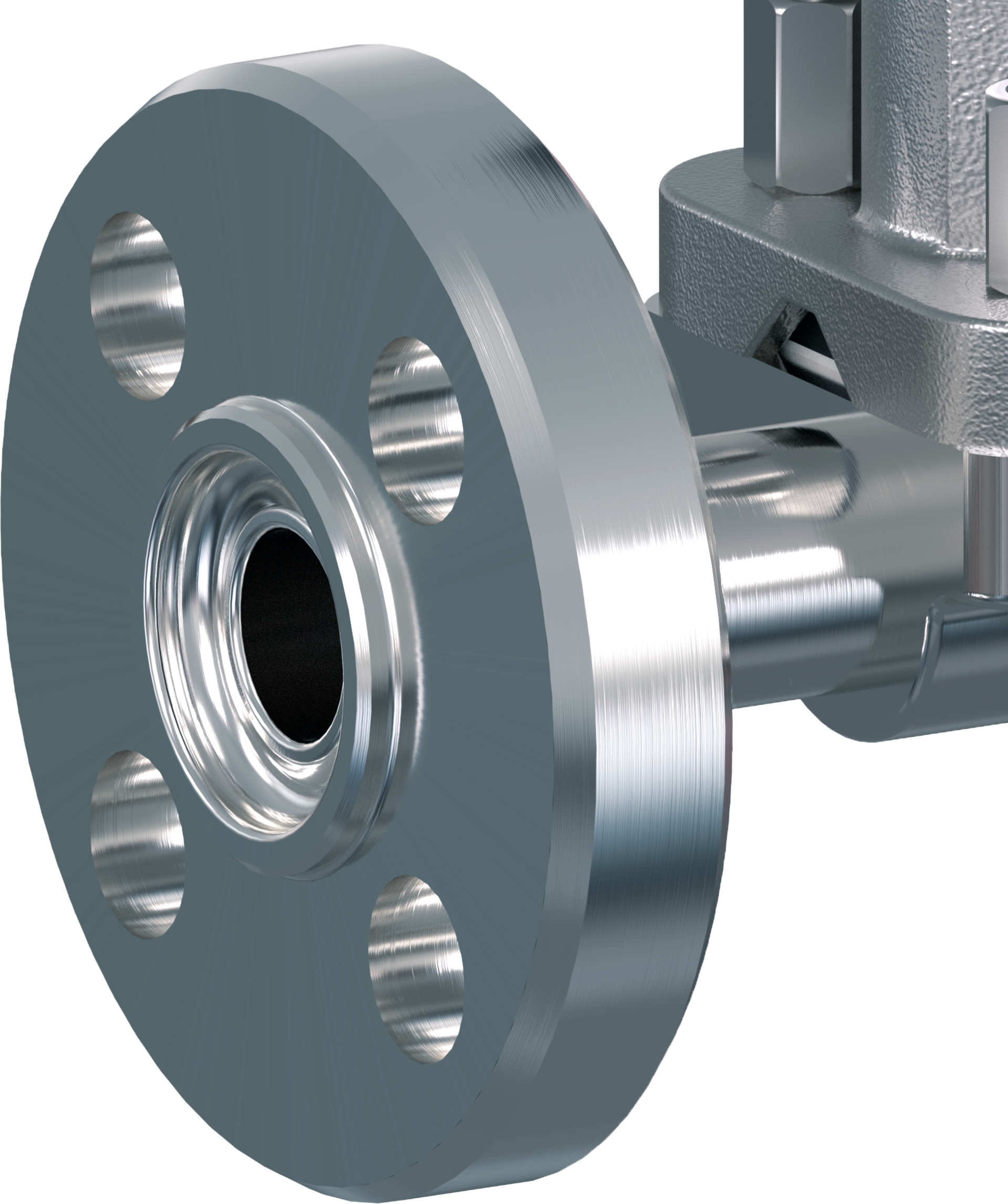

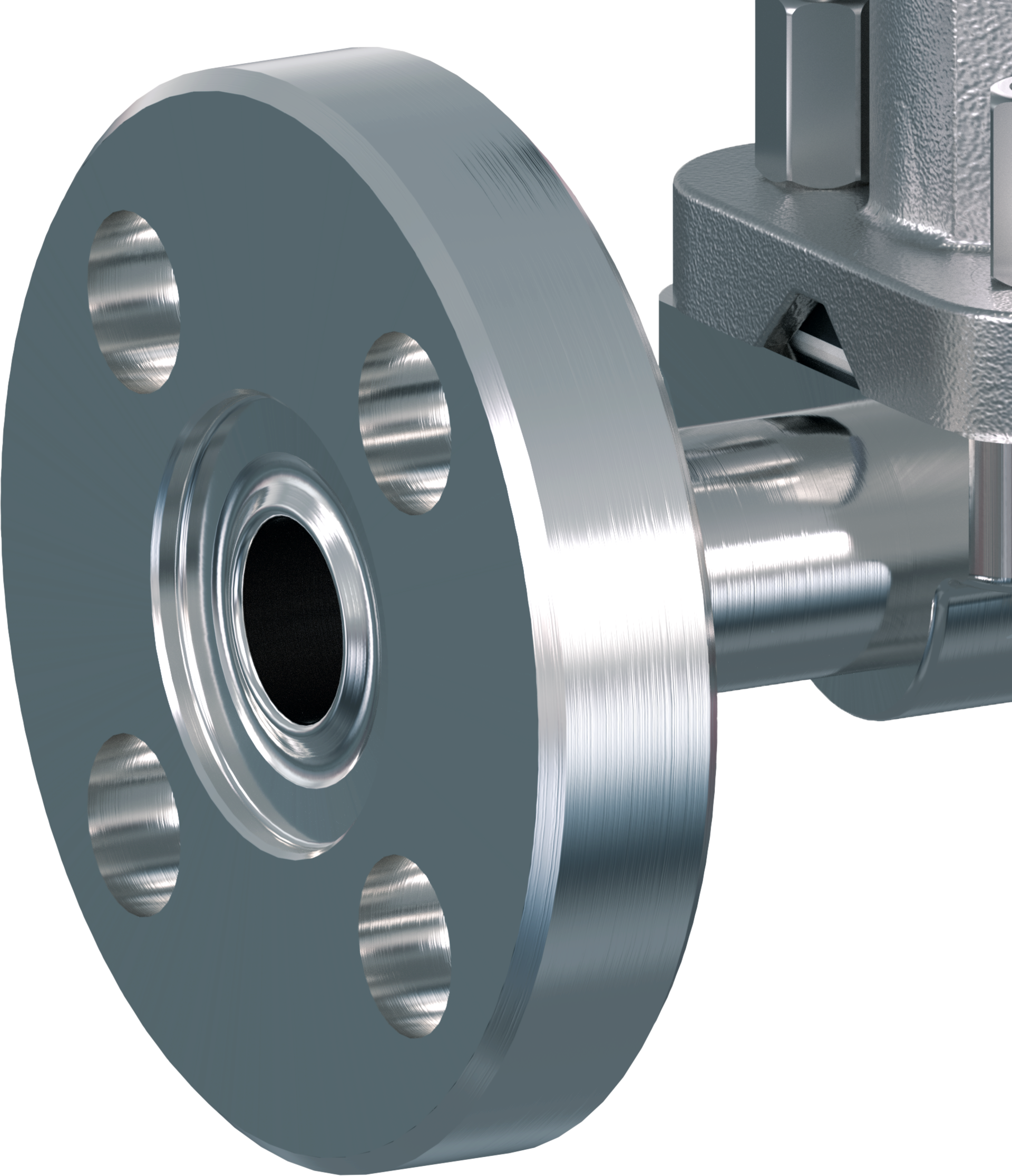

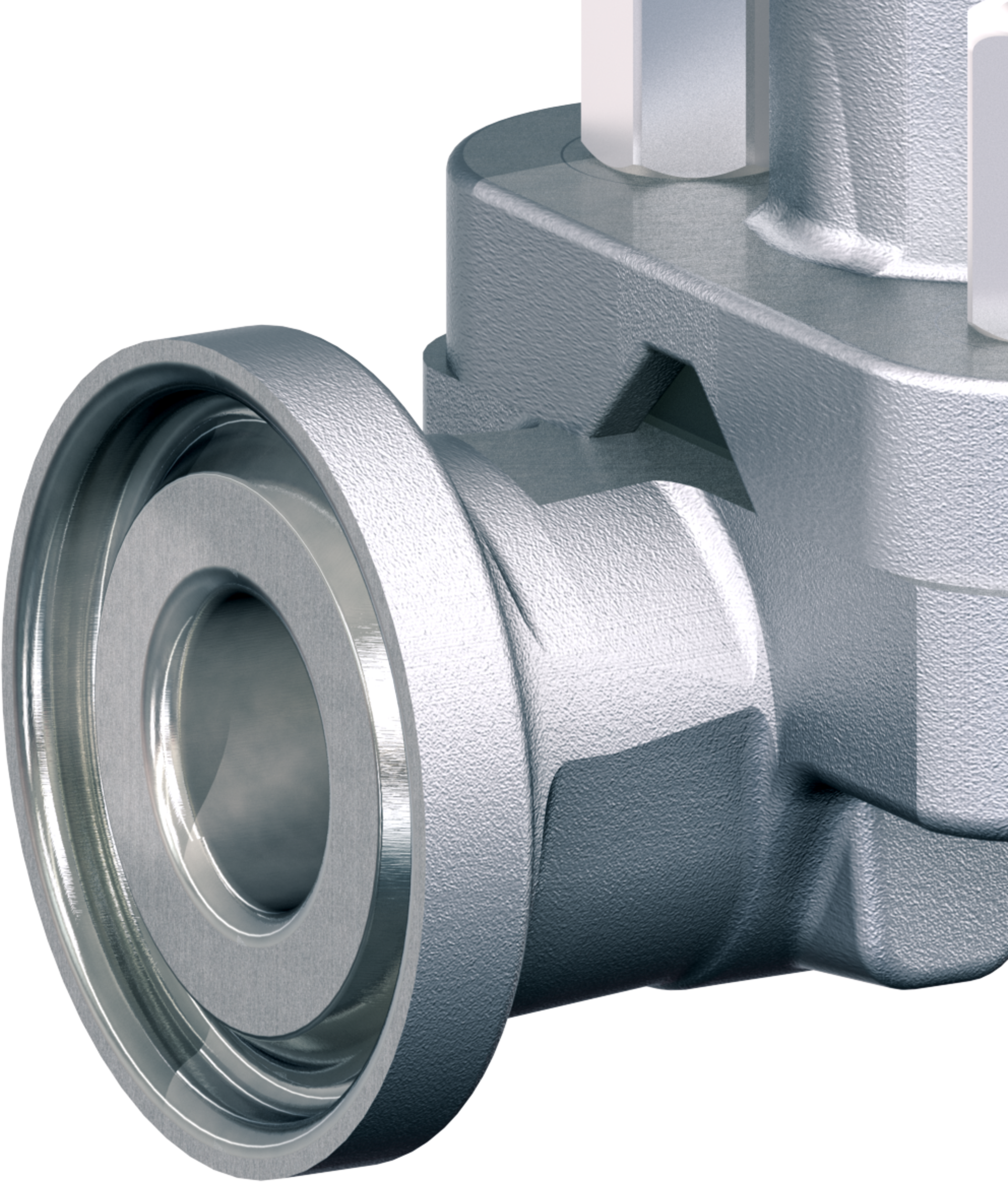

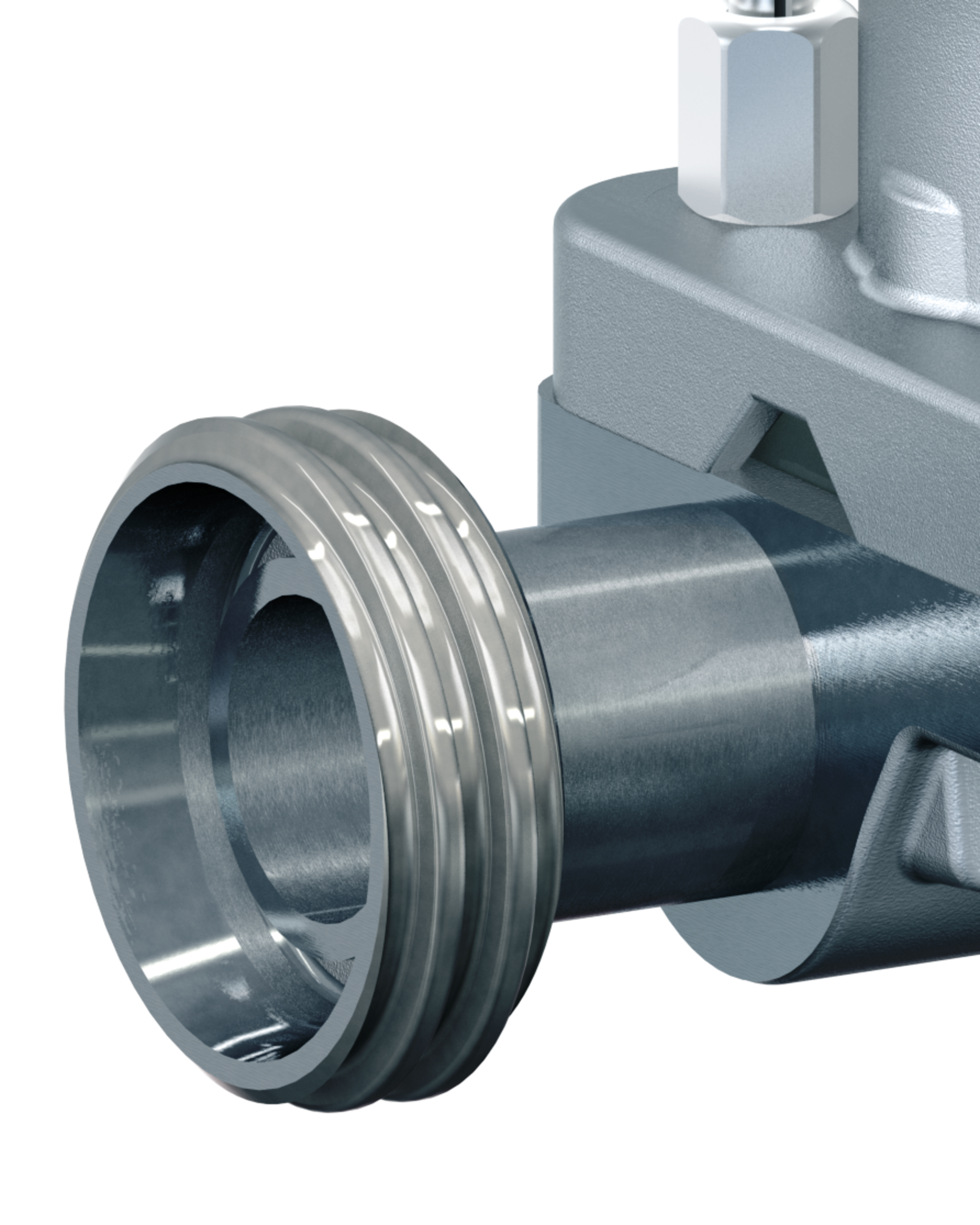

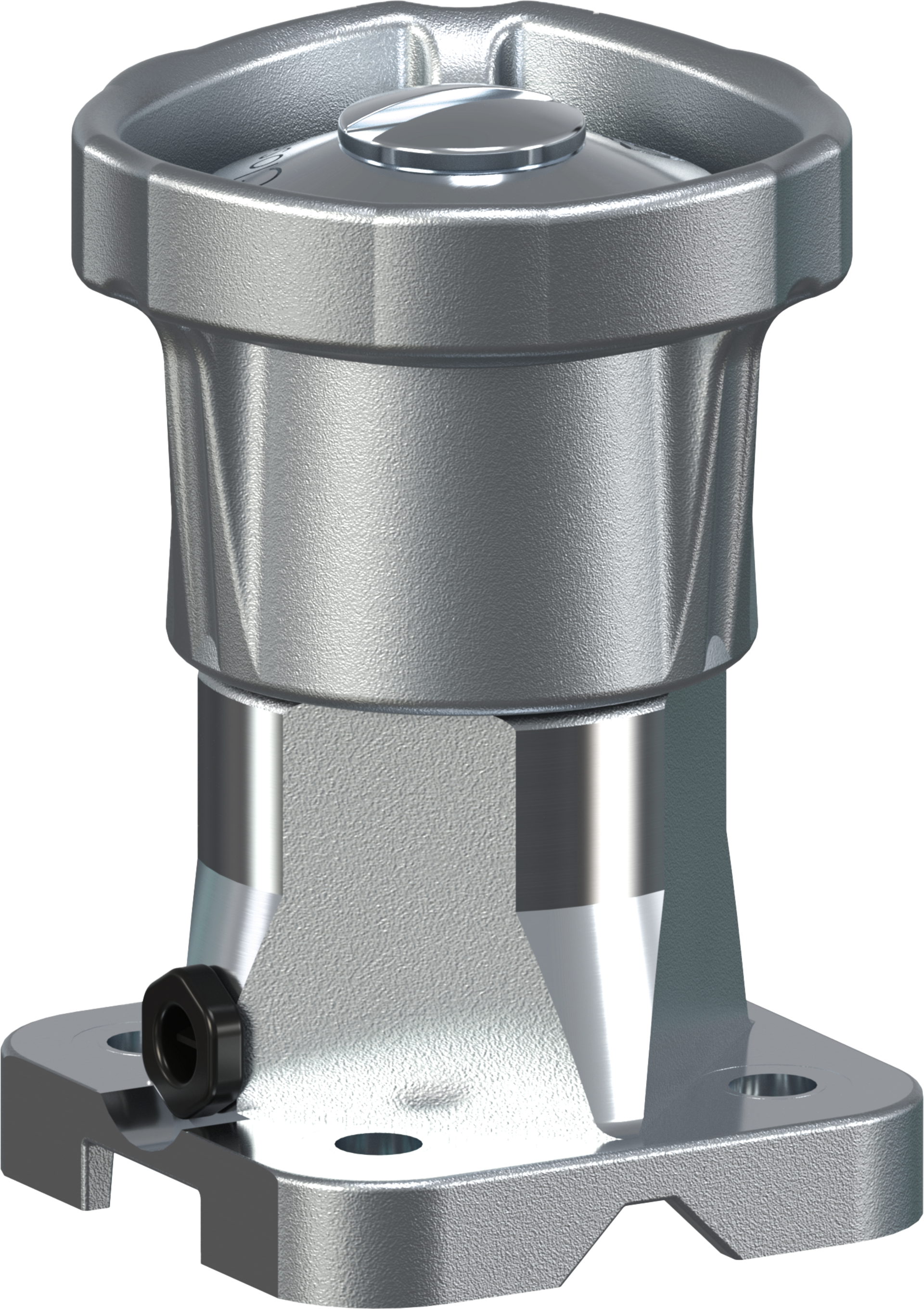

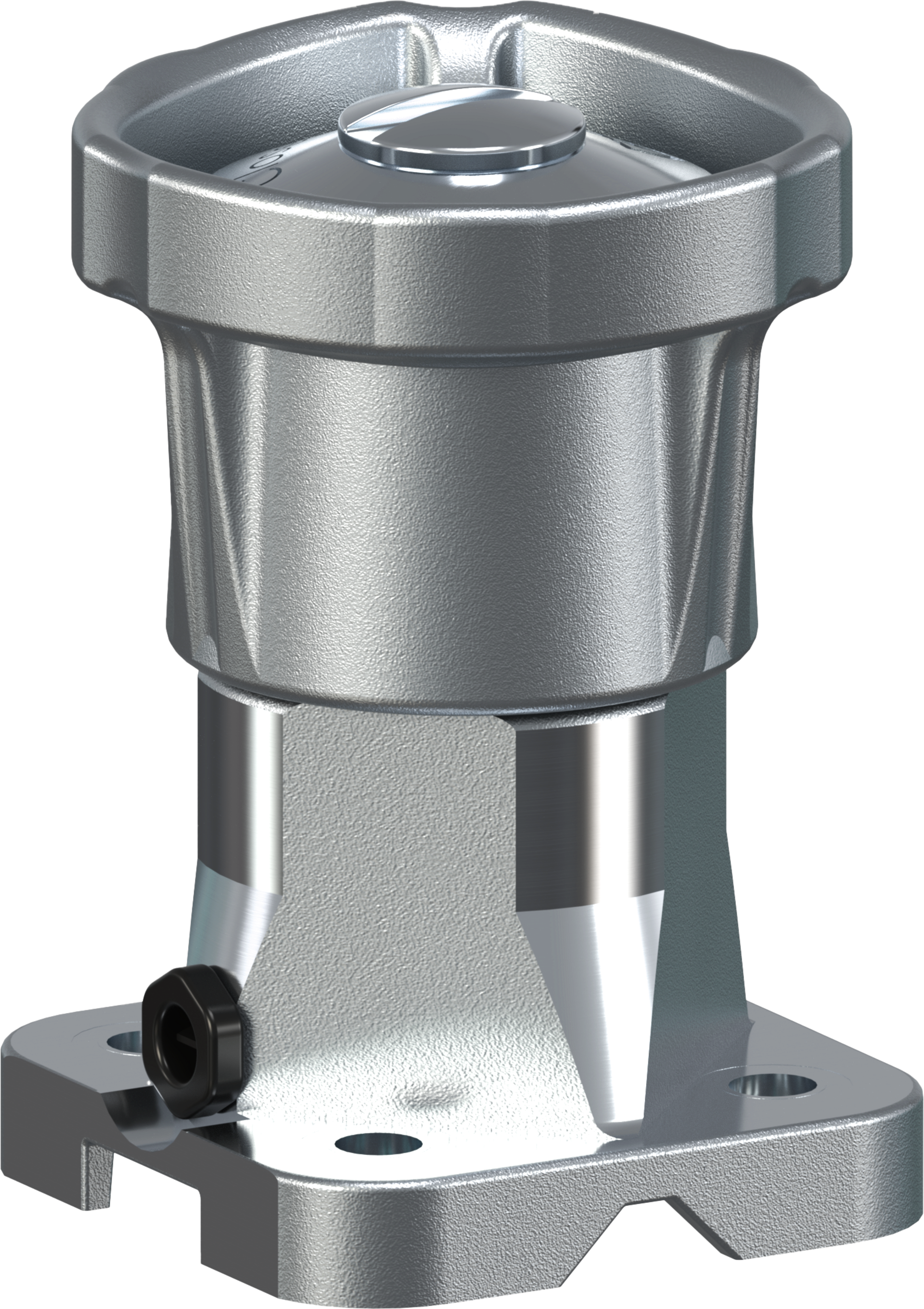

Valve body

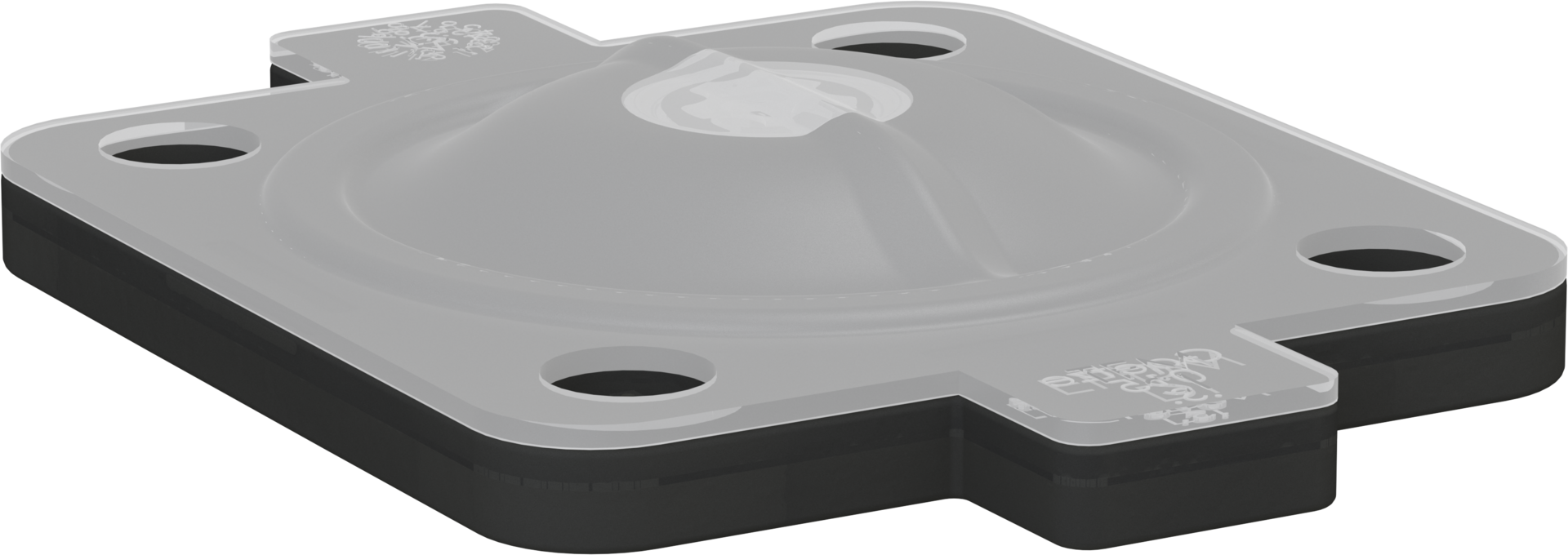

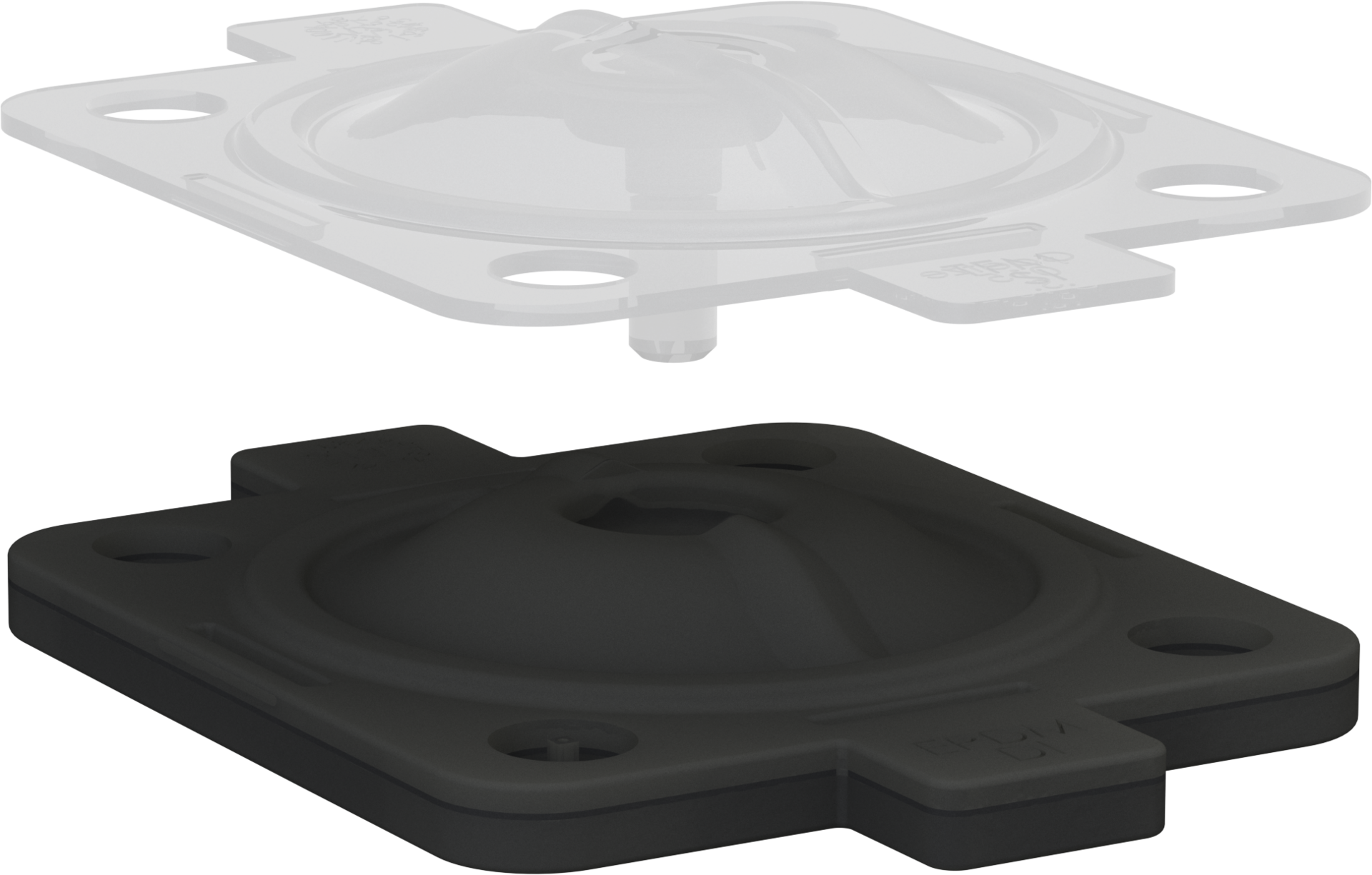

Shut-off diaphragms

Nozzles and fittings

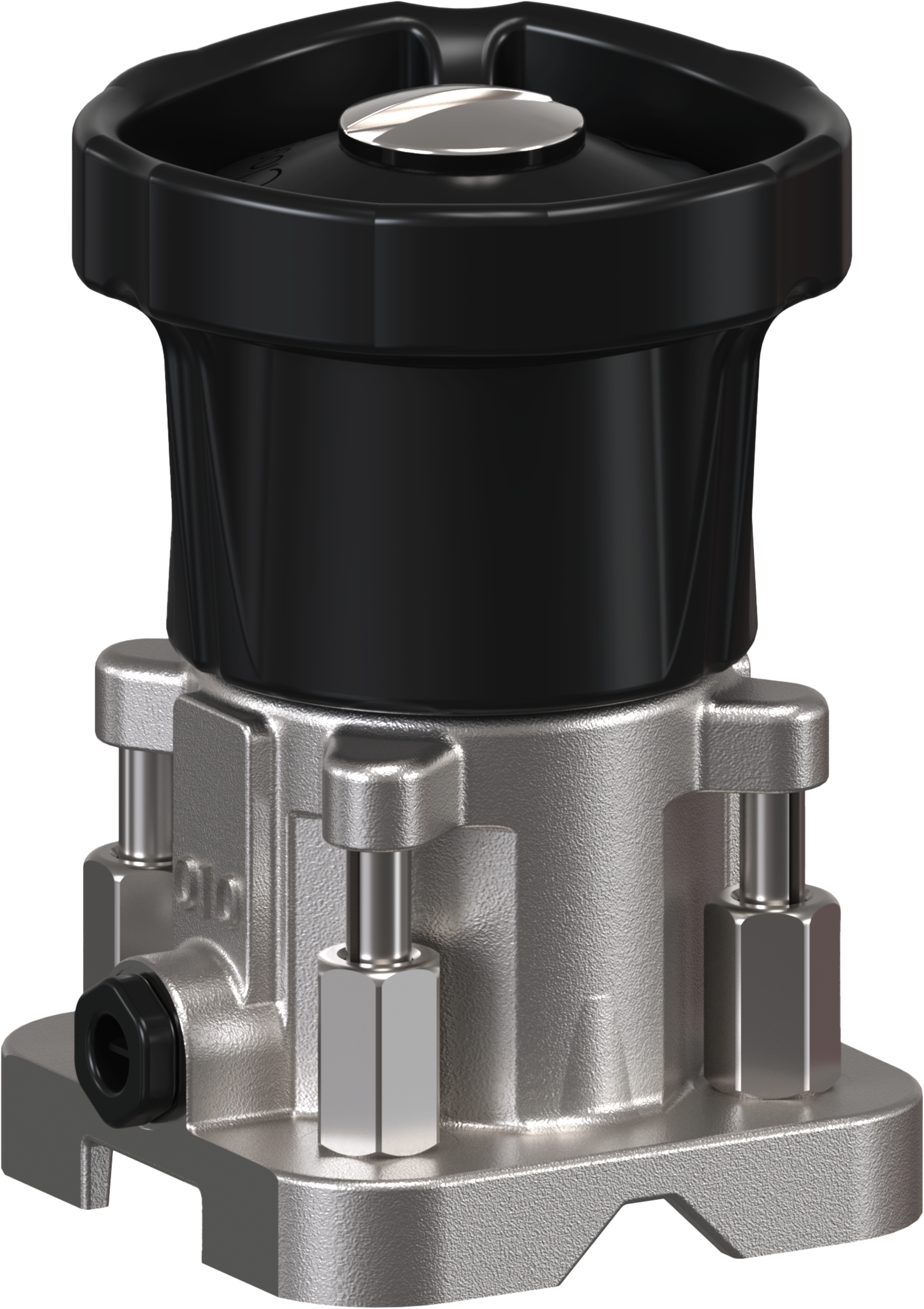

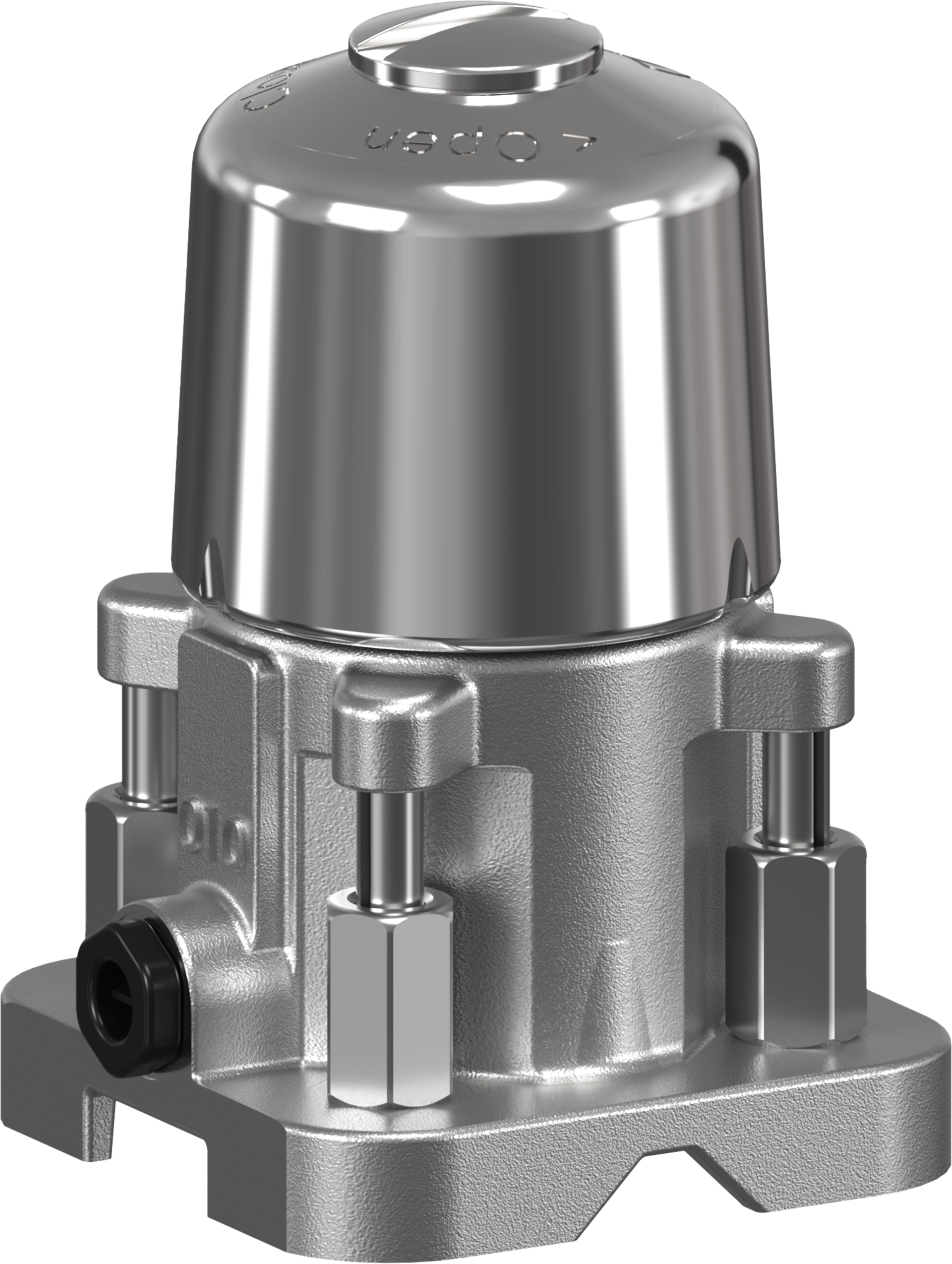

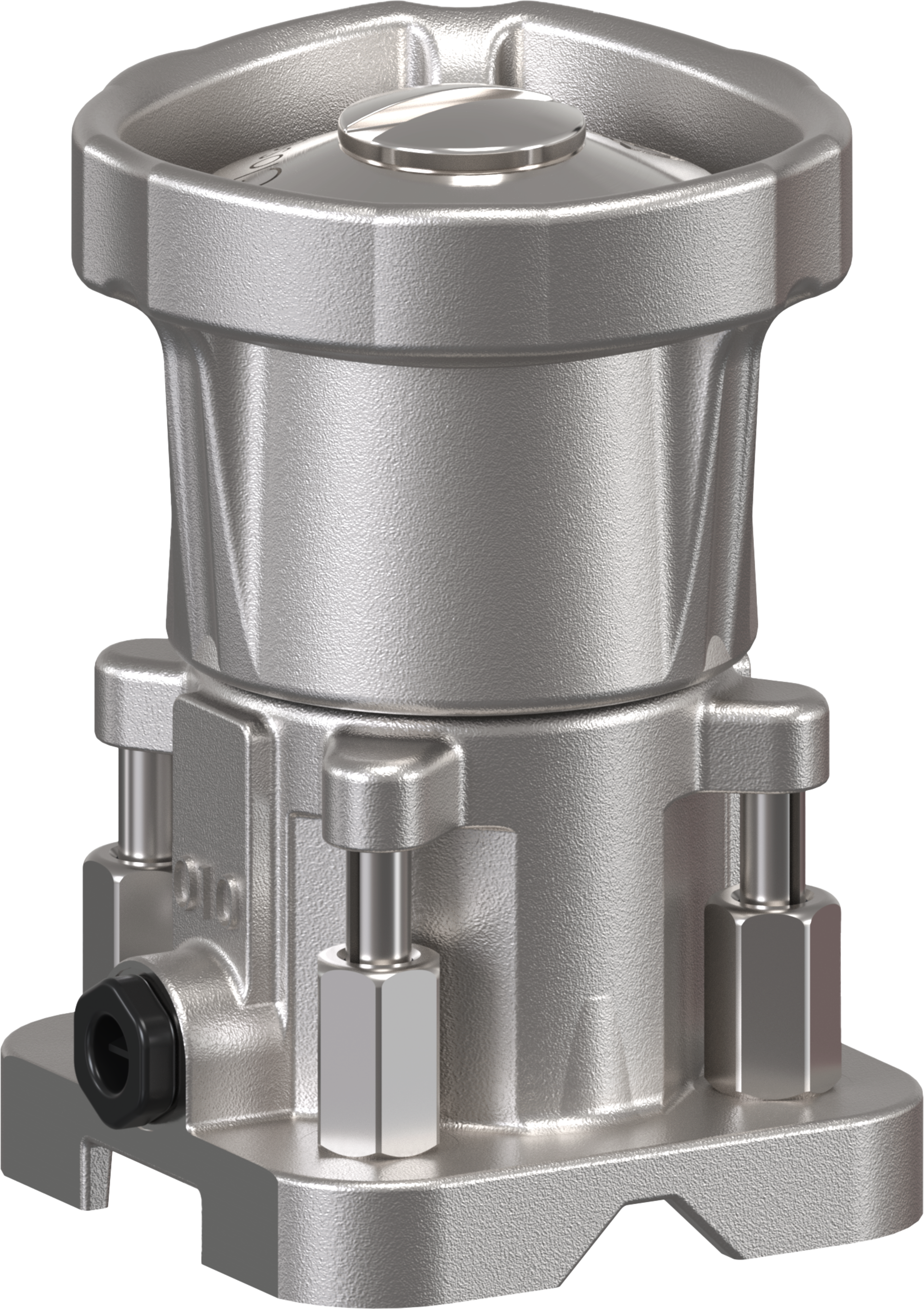

Manual or pneumatic actuators

Our experts will advise you from the outset.

Our strength lies not only in technology, but also in our understanding of your industry.

Whether you are in the pharmaceutical, biotech, food & beverage or cosmetics industry, we understand the specific requirements and develop solutions that integrate seamlessly into your processes.

We focus on personal consultation: in direct dialogue with our product experts, you receive support that is tailored precisely to your plant and your needs. From the initial idea to the final implementation, we accompany you step by step – reliably, individually and in partnership.

Contact the team

Also relevant:

Our path to diaphragm

valves – GOETZE quality reimagined

With clean technology for production processes that place the highest demands on hygiene and cleanability, we are now entering the new field of diaphragm valves. Find out what considerations, tests and technical developments went into the new 40000 series – and how this resulted in solutions that set new standards in aseptic processes.

Answers about deployment, testing and quality.

Frequently asked questions about Goetze Diaphragm valves

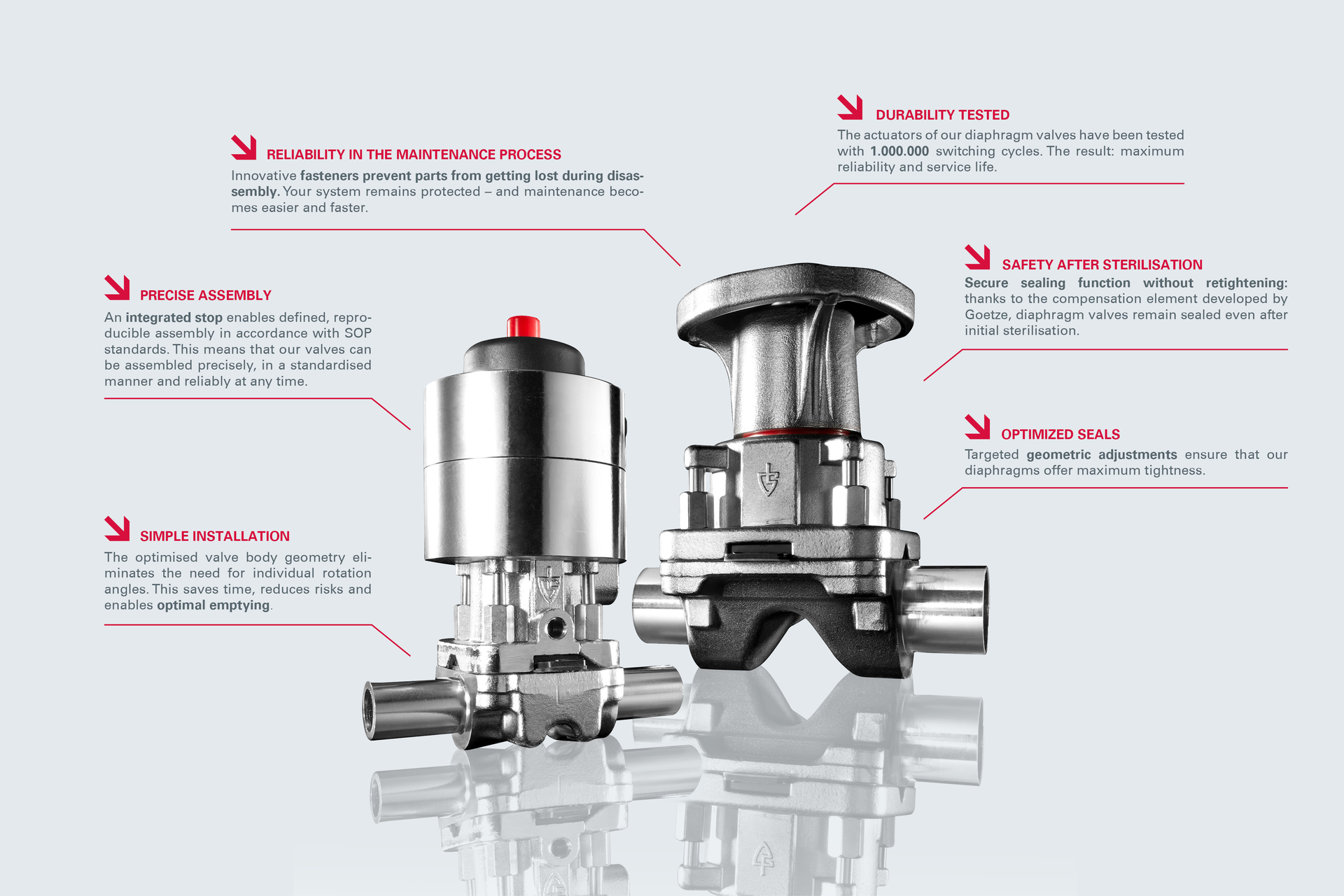

Goetze diaphragm valves have been completely redesigned to meet the special requirements of hygiene-critical applications. A key difference is the patented compensation element, which ensures reliable sealing performance even after initial sterilisation – without the need for retightening. This protects the integrity of sterile processes and minimises the risk of leaks and contamination. In addition, innovative fastening elements ensure that no parts can be lost during maintenance. Together with the optimised valve body geometry for easy installation and the intensively tested seals (tested to over 1,000,000 switching cycles), Goetze diaphragm valves set new standards in safety, efficiency and durability.

Our valves have been extensively tested for CIP and SIP cycles and tested under real conditions on our process test bench. There, we simulate customer processes with different media such as compressed air, clean steam, hot and cold water, acids or alkalis. Each valve variant had to undergo a complex test programme sized for over 1,000,000 switching cycles – a clear promise of quality.

The diaphragm valves are available in mechanically polished and electro-polished versions. Both variants meet the highest aseptic requirements and can be verified by certificates (e.g. factory certificate 2.2 or inspection certificate 3.1) and documented roughness measurements.

Goetze diaphragm valves are ideal for all hygiene-critical applications in the pharmaceutical, biotech, life science, food & beverage and cosmetics industries. They are specially sized for sterile processes, high purity requirements and reliable tightness.