MAXIMUM SAFETY DESPITE MAXIMUM FLEXIBILITYPRESSURE REDUCING VALVES IN THE CALCINATION PROCESS

In industrial processes, how can it be ensured that risks from leakage, for example, are minimised and yet, or precisely because of this, that regular maintenance is as simple as possible?

Pressure reducing valves in steel mill calcination processes face a number of challenges and must be properly sized, manufactured and installed to ensure operator safety and process efficiency.

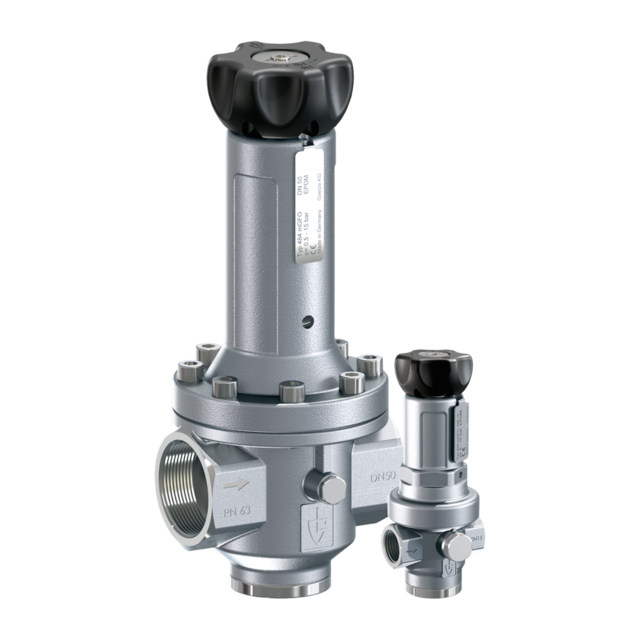

In calcination, our GOETZE pressure reducing valves contribute to safety by maintaining the correct pressure at various points in the system.

GOETZE pressure reducing valves for increased safety in industrial processes.

During the calcination process, temperature, pressure and compressed air flow are carefully controlled to ensure the efficiency of the process and the safety of the operator. GOETZE pressure reducing valves are an important component in this process to ensure that the compressed air pressure remains within the specified limits.

Matching:

Our flyer on the use of pressure reducing valves in industrial calcination processes.

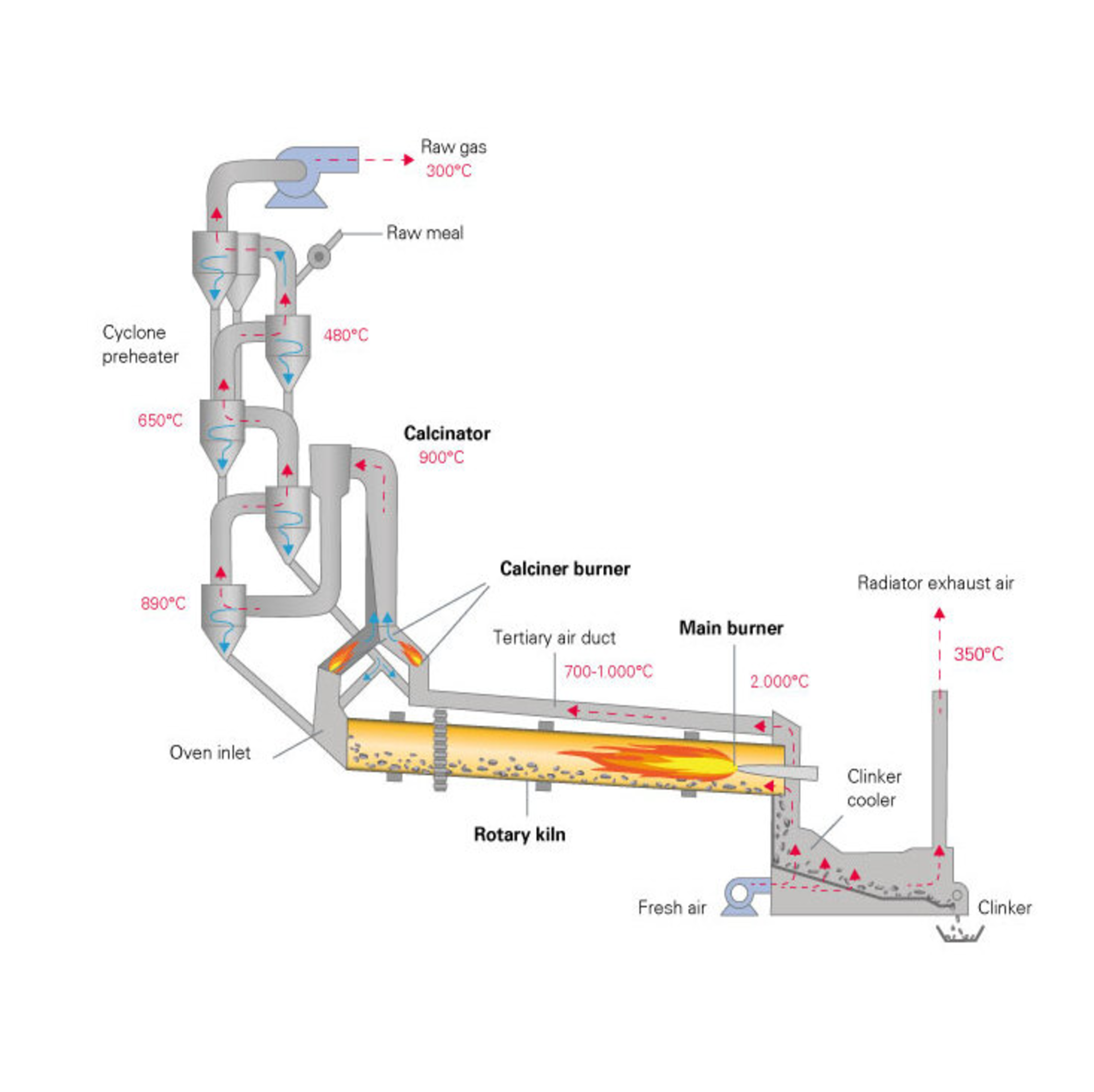

BRIEFLY EXPLAINEDWhat is calcination?

In technical chemistry, calcination is the heating (burning) of a material with the destination of dehydrating or chemically converting it. Calcination takes place during lime burning, as part of the technical lime cycle. The decomposition products are water, calcium oxide and escaping carbon dioxide (CO2).

The solid residue that results from the calcination of hard coal is coke, which consists mainly of carbon and ash. Coke is then used as fuel in the blast furnace to produce pig iron, which is the basic material for steel production.

During coke production, compressed air is blown into the calcination process to promote the controlled oxidation of the material. Pressure reducing valves are used to ensure that the air supply always has the right pressure and does not exceed the permissible limit.

What are the tasks of Pressure reducing valves in calcination processes?

The Pressure reducing valves is an important component to ensure that the compressed air pressure remains within the specified limits.

- Process-supporting compressed air (air flow control)When calcining hard coal, a constant air flow is required to maintain the high temperature and ensure complete combustion of the material. For this constant air flow, compressed air is used, which is blown into the furnaces through special pipes or nozzles.

- Temperature control

Compressed air can be used to regulate the temperature when burning hard coal. This is done by using thermostats and control valves that regulate the amount of air blown into the kilns and thus the temperature of the process. - Filter activation

The gases produced during the calcination of hard coal may contain solid particles and other impurities that must be removed before they escape into the atmosphere. The filters used to remove these impurities can be activated with compressed air, which ensures efficient cleaning and extends the life of the filters. - Equipment protection

The use of Pressure reducing valves can help protect equipment used in the calcination process and reduce the risk of damage from excessive air pressure.

AT A GLANCEThe advantages of GOETZE Pressure reducing valves

- Precise regulation

Precise actuation to maintain constant outlet pressure regardless of input fluctuations. Ensures reliable and accurate pressure control. - High quality materials

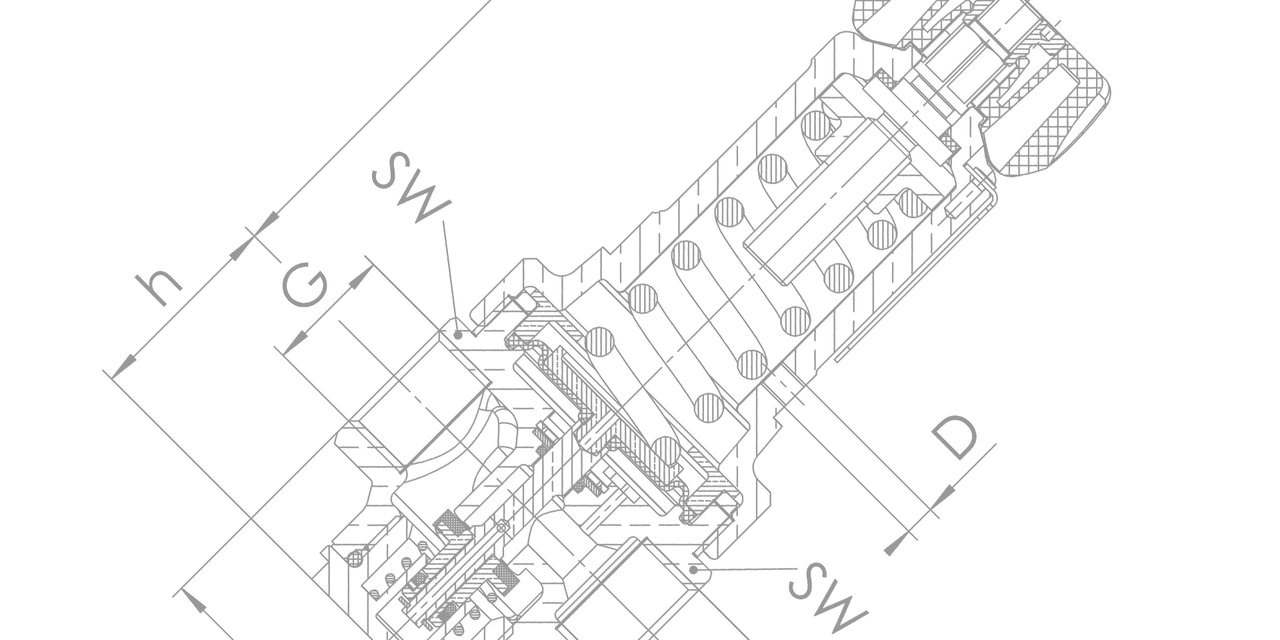

Manufactured from durable, corrosion-resistant materials that ensure long life and minimise frequent replacements. - Simplified maintenance

Design that simplifies maintenance and repairs. Affordable wear parts and easy replacement reduce downtime and maintenance costs. - Certifications and compliance

Compliance with industry standards and certifications that emphasise reliability and safety, such as ASME and PED 2014/68/EU. - Extensive know-how

With decades of experience in the design and manufacture of Pressure reducing valves, we are a trusted partner around the world. We are a supplier to the world's second largest alumina refinery in Brazil. - Customer support and training

We offer comprehensive support and technical advice to our customers - online or in person.

What are the challenges for Pressure reducing valves in calcination processes?

Pressure reducing valves are critical components in the calcination process in steel mills and face some unique challenges in terms of their safe and efficient operation. These are some of the most common challenges:

- High temperatures

During calcination, kiln temperatures can reach extremely high levels, which can affect the performance of Pressure reducing valves. Valves must be sized and made of suitable materials to withstand high temperatures without damage or malfunction.

The GOETZE solution: High temperature diaphragm valves

- Fine dust

Calcination can produce fine, abrasive particles that can affect the operation of Pressure reducing valves. It is important to ensure that Pressure reducing valves are installed in appropriate locations and regularly maintained to prevent the accumulation of particles that can affect the performance of the pressure reducing valves.

The GOETZE solution: The waterproof bonnet design and diaphragm protect the moving parts and prevent contamination.

- Leaks

Compressed air leaks can lead to a loss of process efficiency and in some cases pose a safety risk to operators. It is important to ensure that Pressure reducing valves are correctly sized and installed in accordance with applicable standards to prevent leaks and minimise the associated risks.

The GOETZE solution: Our experts are at your disposal for technical advice and suitable sizing of Pressure reducing valves.

- Pressure adjustment

Pressure reducing valves need to be adjusted frequently during the calcination process to maintain adequate pressure at different points in the system.

The GOETZE solution: Simple adjustment with crank option with excellent setting accuracy.

DO YOU HAVE ANY QUESTIONS? Looking forward to helping you!

Pascal Joos

Business Development

"In the Water Applications Worldwide division, I am responsible for the Water & Building business unit. With my background as an industrial engineer and my experience at Goetze, I develop concepts that strengthen existing customer relationships and open up new markets."

Phone: +497141 48894676