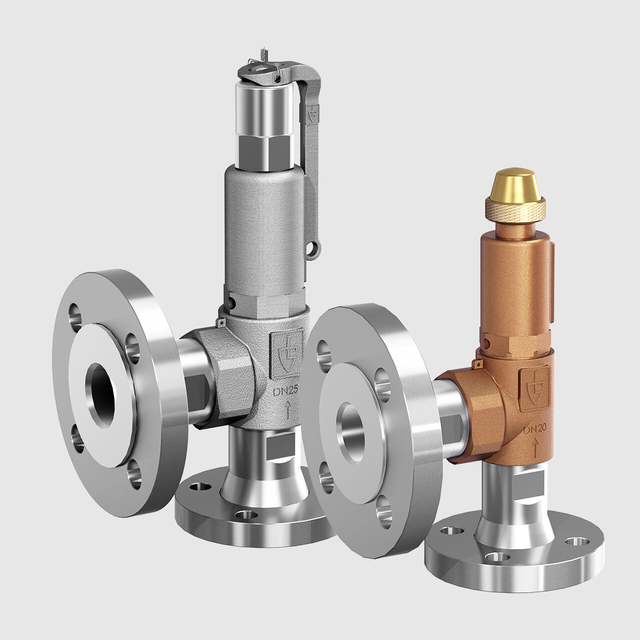

RELIABLE PROTECTION WITH LOOSE FLANGESMaximum flexibility during assembly

The energy turnaround has now reached everyone - including our safety valves:

New ways of generating and storing energy require ever more specialised equipment for processing. Here, too, reliable protection with flange safety valves is essential.

Flanges are used as components for sealing, connecting and closing pipes or enclosures. The tight connection between two components results from the high contact pressure of bolts and nuts. This ensures that the connection is leak-free.

Loose flanges - GOETZE is your partner in safety here too.

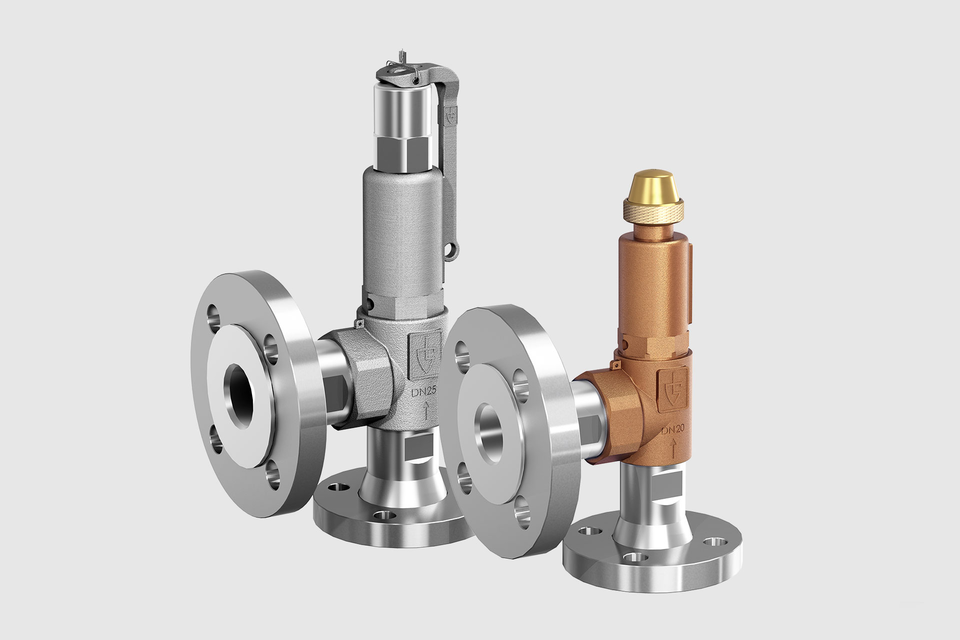

As the name suggests, the flanges are inserted loosely into piping elements, allowing free alignment of the valve. This type of valve is often used when the final position has not yet been determined when installing the piping and the counter flange.

This mainly applies to API valves and flange valves in the oil and gas industry. However, loose flanges are also used by GOETZE customers in the chemical industry, in steam applications and also in battery production plants.

INDIVIDUALITY FOR MORE SAFETYTested quality and individual design

Our loose flanges of the 451FL and 851FL series have DIN and ASME approval with ANSI flanges for liquids, vapours and gases. Whether according to DIN EN 1092-1 or ASME B 16.5, solutions are available in different pressure ratings and nominal sizes.

On the inlet side, our safety valves have a full nozzle due to the loose flange or the design of the inlet. This means that the valve inlet and valve seat are in one piece. Full Nozzle is a must in the flange area for critical applications.

The hole pattern of the inlet and outlet can be individually adapted to the pipeline at GOETZE. Thanks to the movable flange blade, the hole pattern can be positioned when installing the safety valve so that the pipeline does not have to be changed on the outlet side and the valve is safe and operates tightly.

QUALITY AND RELIABILITYFrom individual components to worldwide shipping.

ANSI loose flanges are produced in house for stock, which makes fast delivery of valves possible.

To ensure good durability, the loose flanges are manufactured from 4404/316L - high quality chrome nickel steel. In combination with a full nozzle and a PTFE flat gasket or a metallic gasket, the 451FL and 851FL series are predestined for use in extreme temperature ranges or for critical media.

All advantages at a glance:

- efficient safety valve

- individual production of the hole pattern according to DIN or ASME

- different sealing surfaces

- individual leg dimensions

- movable flange leaf

- Full Nozzle Design

- high quality chrome-nickel steel

We can offer loose flanges not only for our safety valves, but also for our pressure reducing valves. Here, for example, the 484 series is used in the field of technical gases when the pressure is to be regulated without large pressure losses.

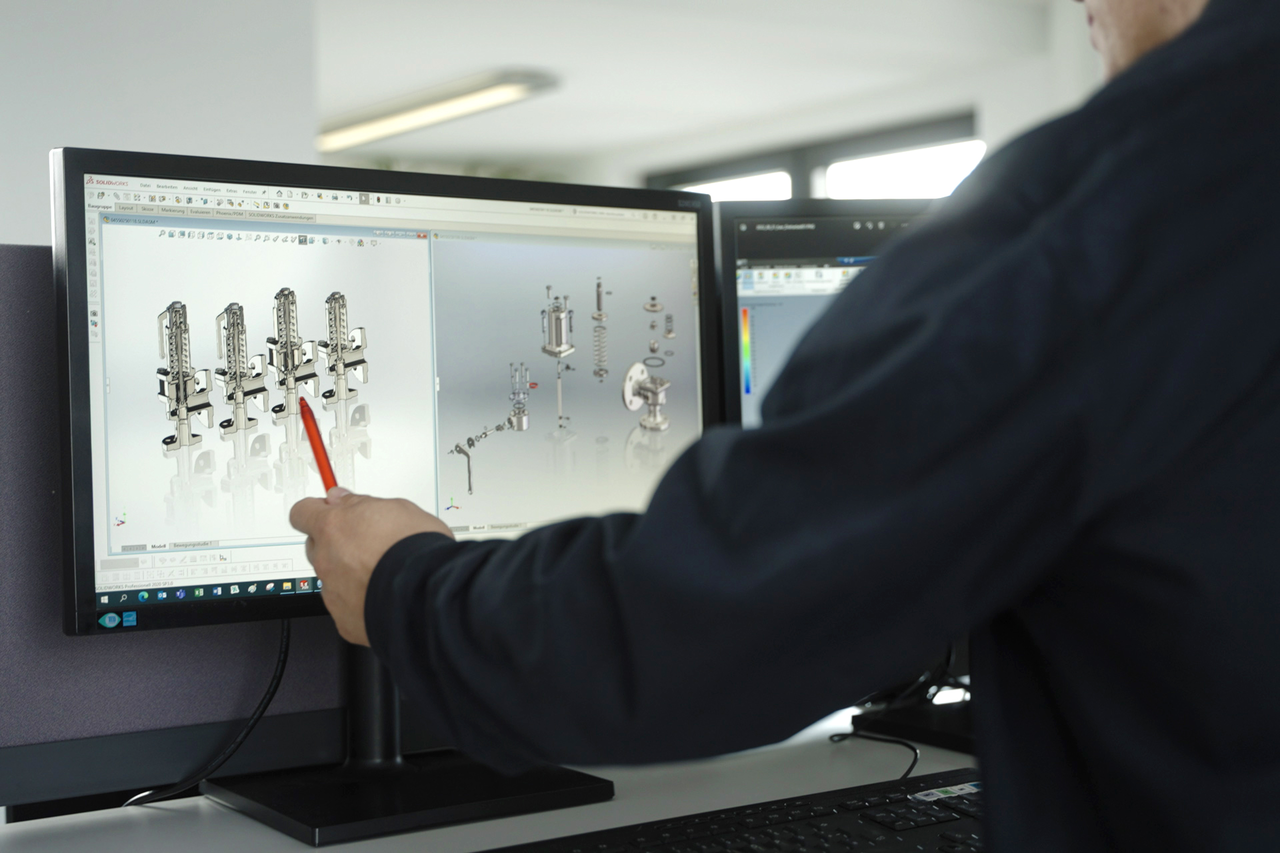

Go2Valves - the sizing software for safety valves at GOETZE

In order to determine the correct size of the safety valve, the Goetze valve experts design the safety valves with our sizing tool Go2Valves. At the inlet, we can cover a nominal size of loose flanges up to 3".

DO YOU HAVE ANY QUESTIONS? Looking forward to helping you!

Olaf Schulenberg

Business Development

"I am responsible for the Industrial, Technical Gases and Cryogenic business units and support our customers with customised solutions and in the sizing of safety valves. I am also involved in standardisation committees and am responsible for the northern Germany and Netherlands sales region in the field service department."

Phone: +497141 48894670